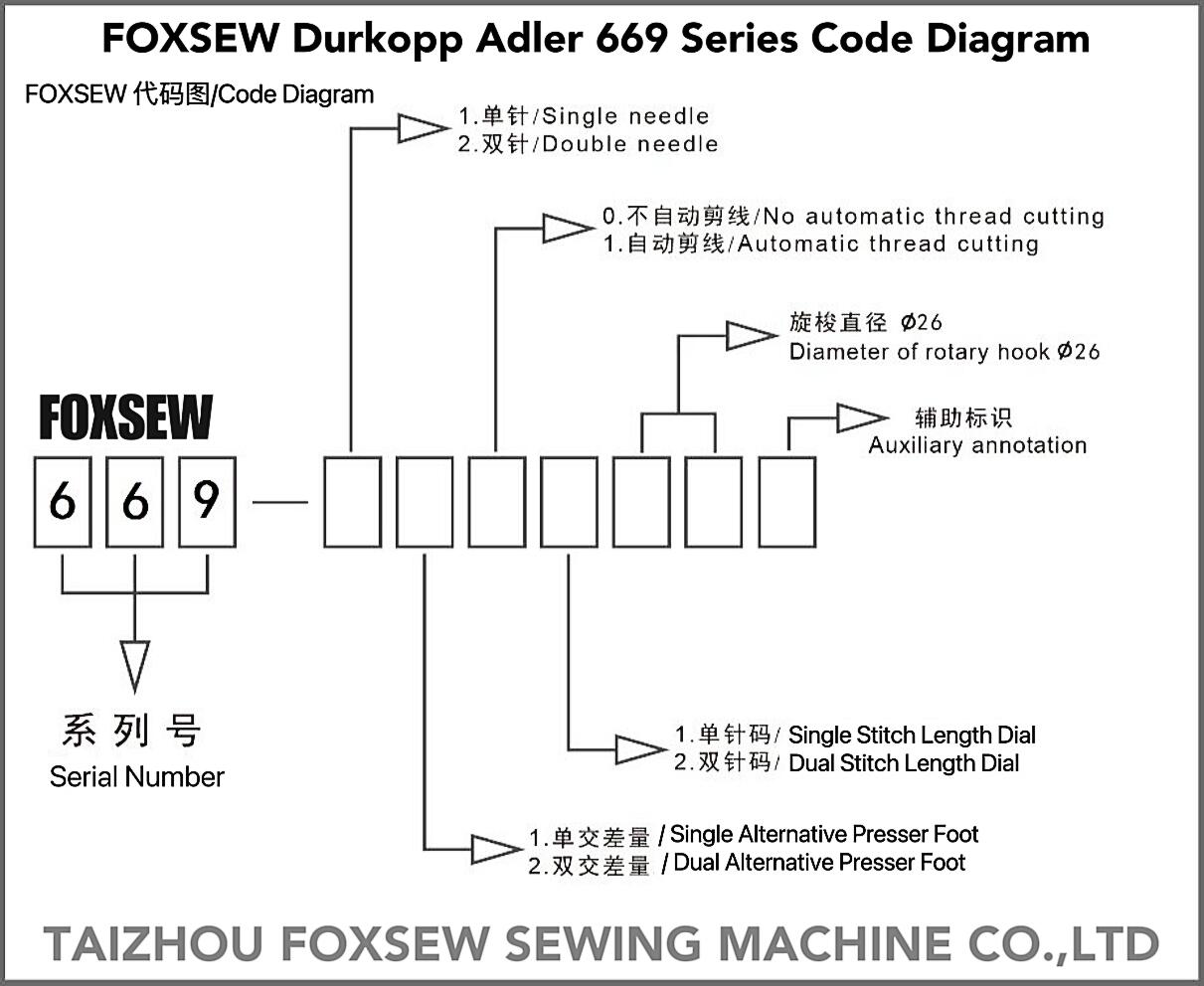

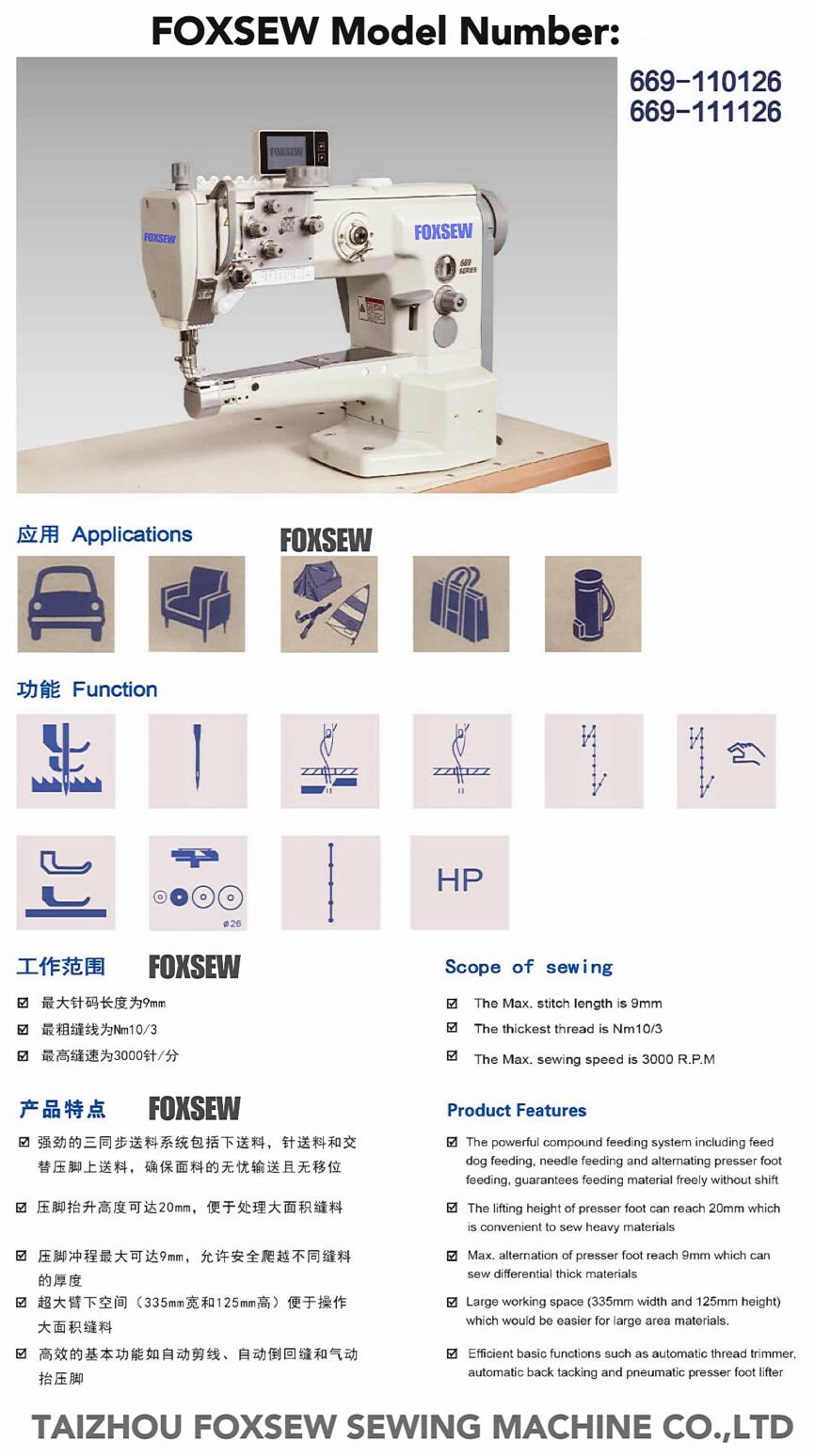

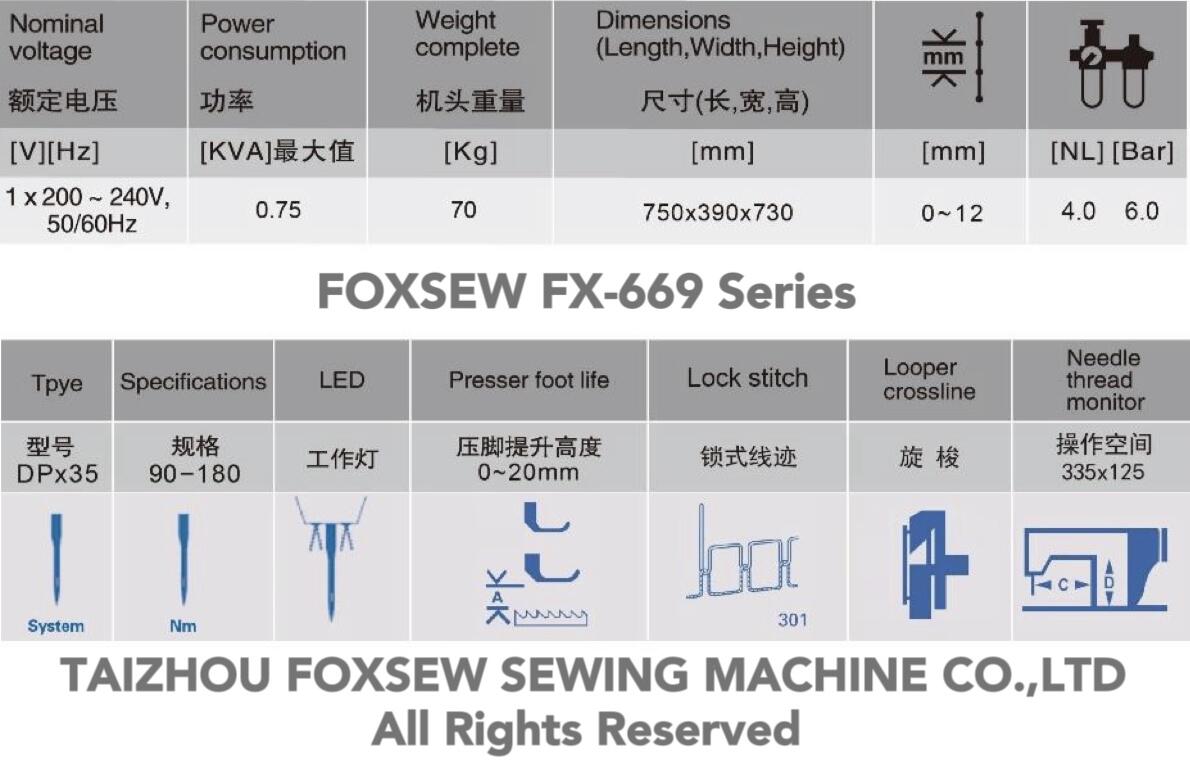

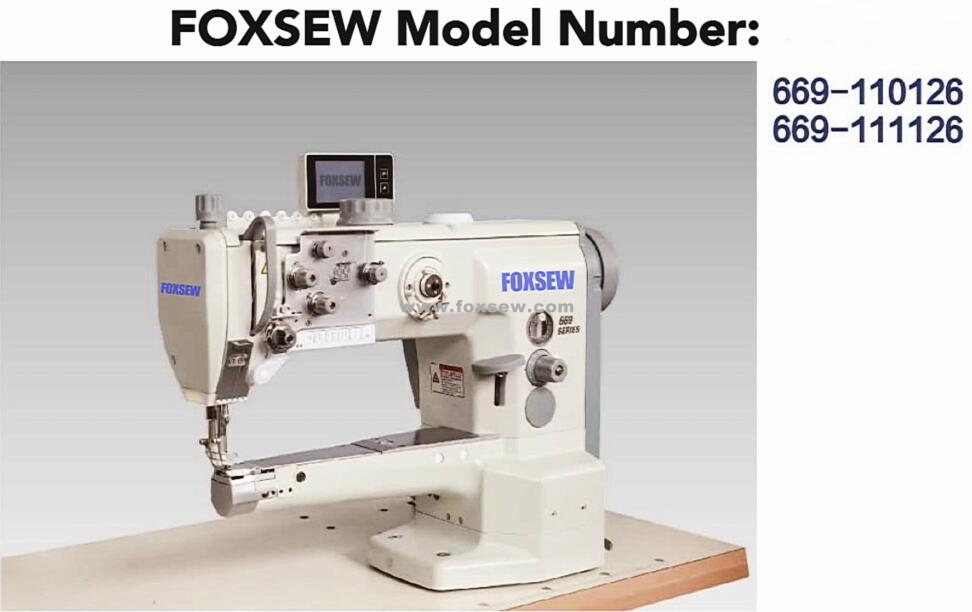

- Product Name: Durkopp Adler 669 Classic Cylinder Arm Sewing Machine

- Model NO.: FX-669-111126

- Origin: Zhejiang, China

- Packing: Cartons

- Brand Name: FOXSEW

- Quality System Certification: CE

-

Product Details: Durkopp Adler 669 Classic Cylinder Arm Sewing Machine

FOXSEW Durkopp Adler 669 Classic Cylinder Arm Sewing Machines Series

Durkopp Adler 669 Series Cylinder Arm Leather Sewing Machines

Applications for Sewing Handbags, Leather Bags, Wallets, Leather Belts, Shoes, Leather Straps, Luggage, Suitcase, Football, Hot Air Balloon, Cushion, Chaps, Headstalls, Purses, Leather Bags, Jackets, Vests, Belts, Upholstery, Saddlebags, Boots, Harness, Furniture Upholstery, Automotive Interior Upholstery, Suitcase Handles, Saddles, Leather Sofas, Fabric Sofas, Leather Armchairs, Leather Recliners, Bags, Baseball Gloves, Sports Products, Safety Bags, Toys, etc...

Durkopp Adler 669 Cylinder Arm Leather Sewing Machine

Durkopp Adler 669 Classic Cylinder Arm Sewing Machine

Durkopp Adler 669 Series Cylinder Arm Heavy Duty Sewing Machine

Durkopp Adler 669 Type Cylinder Arm Leather Sewing Machine

Durkopp Adler 669 Classic Cylinder Arm Leather Sewing Machine

The M-TYPE cylinder arm machines with electro-pneumatic full equipment and triple feed are equipped with all M-TYPE-typical performance features and advantages.

In addition to the automatic basic functions such as thread trimmer, automatic backtacking and automatic sewing foot lift, the subclasses of the CLASSIC Goldline cylinder arm series convince with further additional functions for higher productivity and increased sewing comfort.

Furthermore the integrated second thread tension, integrated second stitch length and quick stroke adjustment allow to produce with the highest quality in a particularly flexible and efficient way even for changing and difficult sewing applications. Furthermore, the full equipment of the M-TYPE is complemented by additional comfort functions: The optimum illumination of the sewing area and the maintenance indicator ensure the best possible design of the sewing workstation.

The powerful and effective feeding system with bottom feed, needle feed and alternating top feet guarantees a trouble-free and displacement-free material feed when processing most different fabric thicknesses and structures. The highly efficient sewing parameters combined with a great variety of equipment make the CLASSIC Goldline cylinder arm machines an ideal operating equipment for special sewing tasks in three-dimensional or tubular workpieces in the field of technical textiles, shoes and leather goods, soft luggage and comparable products.

Flexible and efficient sewing in changing sewing conditions by integrated second thread tension, integrated second stitch length and quick stroke adjustment.

Reduced process times due to automatic basic functions like thread trimmer, automatic sewing foot lift and automatic backtacking.

Integrated keypad with ergonomically arranged favourite key.

Easy feeding and removing of bulky workpieces thanks to the extremely high sewing foot lift up to 20mm.

Safe climbing over differently high material plies by maximum sewing foot stroke up to 9mm.

The machine class FOXSEW FX-669 Series reach a very slim machine arm diameter of only 50mm, which enables the handling of difficulty accessible seam areas.

The machine class FOXSEW FX-869 Series is available as a 2-needle version.

Central oil wick lubrication (minimal lubricating system).

Sewing processes on tubular workpieces make highest demands on the qualification of the operator and on the efficiency of the sewing technology.

The subclasses of the new M-TYPE free arm machine FOXSEW FX-669 Series with particularly slim machine arm make it possible to professionally realize difficult sewing processes like assembly and binding operations as well as decorative stitching on small leather goods and difficultly accessible or tubular workpieces.

A special feature of the FOXSEW FX-669 Series is its ability to bind the material edge with low tension. For this operation the bottom feed stroke can be deactivated by just a few steps which enables an optimum feeding movement. Sewing equipment especially adapted to this sewing operation allows a precise binding result combined with maximum productivity and quality. Due to outstanding performance parameters the FOXSEW FX-669 Series ECO offers high functionality and flexibility, at an attractive price.

FOXSEW FX-669 Series Machines' advantages:

FOXSEW FX-669 Series ECO high functionality and flexibility at an attractive price

Slim machine arm diameter of only 50 mm facilitates the handling of difficultly accessible seam areas

Adjustable bottom feed (with stroke for topstitching operations, without stroke for binding operations)

Quick change to binding applications

New hook with large bobbin capacity for longer sewing cycles and a wider sewing thread spectrum

High productivity due to increased speed up to 3,000 stitches/min.

Excellent climbing properties avoid shortened stitches and material damage at thick spots or cross seams

Smooth, adapted sewing and feeding properties

New hook cover allows time-saving bobbin change

Manual additional thread tension for excellent stitch formation when sewing over thick spots

Safety clutch protects against hook damage

New lubricating system with adjustable hook lubrication

Sewing drive fastened at the machine head

FOXSEW FX-669 Series Eco / cylinder arm walking foot leather upholstery sewing machines

The powerful and effective feeding system with bottom feed, needle feed and alternat-ing feet guarantees a trouble-free and dis-placement-free material feed when process-ing most different fabric thicknesses and structures

The extremely high sewing foot lift up to 20mm max. facilitates the feeding and removing of bulky workpieces

High top feed stroke up to 9mm allows the safe climbing over thick material plies

Up to 9mm long stitches for standard seams and decorative topstitching

The large clearance (335mm wide and 125mm high) facilitates the handling of tubular workpieces

Excellent view on the sewing area

Integrated bobbin winder with winding starting aid

Maintenance-friendly design

Low noise level

Automatic backtacking, (CLASSIC)

Integrated second stitch length (CLASSIC Goldline)

Integrated LED sewing lamp for a shadow-less lighting of the sewing point (CLASSIC)

Integrated 6-function keypad with ergonomi-cally arranged favourite key (CLASSIC)

Integrated maintenance indicator (CLASSIC)

The complete range of sewing equipment, attachments and optional equipment guar-antees the optimum equipment solution for nearly all sewing operations

Servo motor 110v or 220v single phase

Space saver heavy duty table top with heavy duty stand

Sew tested to your specific application (included)

Large capacity bobbin

7" cylinder arm diameter (sew area)

-

Product Images: Durkopp Adler 669 Classic Cylinder Arm Sewing Machine

-

Super Slim High Post Bed Compound Feed Heavy Duty Lockstitch Sewing Machine

-

Super Slim Post Bed Top and Bottom Feed Lockstitch Sewing Machine

-

U-Shape Rotation Arm Handbag Sewing Machine

-

Durkopp Adler 669 Direct Drive Cylinder Bed Sewing Machine

-

Durkopp Adler 669 Classic Cylinder Arm Leather Sewing Machine

-

Durkopp Adler 669 Type Direct Drive Cylinder Arm Sewing Machine

-

Durkopp Adler 669 Type Cylinder Arm Leather Sewing Machine

-

Durkopp Adler Classic 669 Direct Drive Cylinder Arm Sewing Machine

-

Durkopp Adler 669 Series Cylinder Arm Heavy Duty Sewing Machine

-

Durkopp Adler 669 Direct Drive Cylinder Arm Sewing Machine